3D-printed Mario Kart turtle shells race to rescue American economy

Adding Value To The World, one Post At A Time

Posted by gjblass at 3:40 PM 0 comments

Labels: 3-d printer, Mario

Posted by gjblass at 2:00 PM 0 comments

Labels: 3-d printer, Planes

Posted by gjblass at 12:15 AM 6 comments

Labels: 3-d printer, Boobs, Bras, Breasts, consumer technology

by Lloyd Alter, Toronto

from: http://www.treehugger.com/

Credit: Stratasys

The Urbee has been an Automotive X Prize candidate and will be on The Discovery Channel's Canadian flagship Daily Planet. The car, designed by Kor Ecologic of Winnipeg, Canada, is an electric / liquid-fuel hybrid that will get the equivalent of over 200 mpg on the highway and 100 MPG in the city.

But it is also the first car ever to have its entire body printed out on a giant 3D printer.

Credit: Stratasys

According to a press release from Stratasys:

Urbee is the first prototype car ever to have its entire body 3D printed with an additive process. All exterior components - including the glass panel prototypes - were created using Dimension 3D Printers and Fortus 3D Production Systems at Stratasys' digital manufacturing service - RedEye on Demand.

The designers at Kor point out the benefits of Fused Deposition Modelling:

"Our goal in designing it was to be as 'green' as possible throughout the design and manufacturing processes. FDM technology from Stratasys has been central to meeting that objective. FDM lets us eliminate tooling, machining, and handwork, and it brings incredible efficiency when a design change is needed. If you can get to a pilot run without any tooling, you have advantages."

The implications for building prototypes are obvious; you go straight from computer to finished part in a lot less time. But imagine a few years down the road, when everyone might order up the car body of their choice from a catalogue and just bolt it on a standard chassis. Ding the side? Just print up a replacement.

Posted by gjblass at 10:56 AM 0 comments

Labels: 3-d printer, automobiles, automotive, Concept Cars, Concept Designs

Recently we showcased a 3D printer that creates human body parts ready for transplant, and now our frankenstinean fascination with making body parts has unearthed another amazing device. This new bio-printer sprays skin cells on burn victim’s wounds, promoting healthy recovery. The printer is mounted onto a frame that is wheeled over a patient’s hospital bed. A laser reads the depth and shape of the wound, and with the help of a computer the device sprays a precise layer of skin cells that can heal infection-prone wounds in just three weeks.

The skin-spraying project is being developed by scientists and students at Wake Forest University in North Carolina. They are planning to team up with U.S. Armed Forces Institute of Regenerative Medicine to use the device to help wounded soldiers returning from overseas. The process starts as skin cells are separated and purified. They are then placed in a nutritious solution that helps the cells multiply. They are then loaded into the device, sprayed on the skin in layers and voila! Burns are healed. So far they’ve only tested the process on mice, and they were able to successfully heal burns after just three weeks.

Traditionally the only way to fix severe burn wounds is a skin graft. Skin grafts are highly painful and generally leave huge scars. With this new process scientists include some stem cells in the mix which allows hair follicles and sebaceous glands develop in the new layers of skin. It seems that when the cells are sprayed on the wound they know exactly what they are supposed to do, and they develop as naturally as a your own skin would. Eliminating the mass amount of medical rehabilitation involved in getting burn victims back on their feet by spraying on skin cells will eliminate much of the painful process and cut down on the chemical-based medicines used to help them heal.

Via Reuters

Posted by gjblass at 2:00 PM 0 comments

Labels: 3-d printer, Artificial Skin, Digital Printing, Human Biology, Human Cloning, Printing Human Organs, Things That Are Awesome

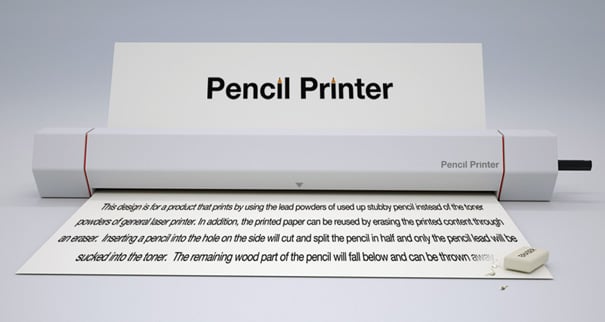

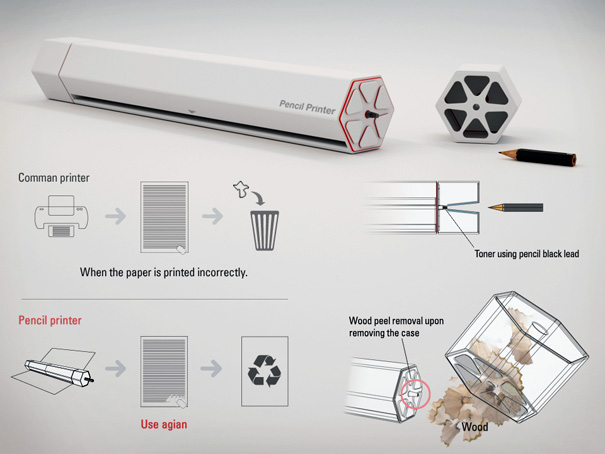

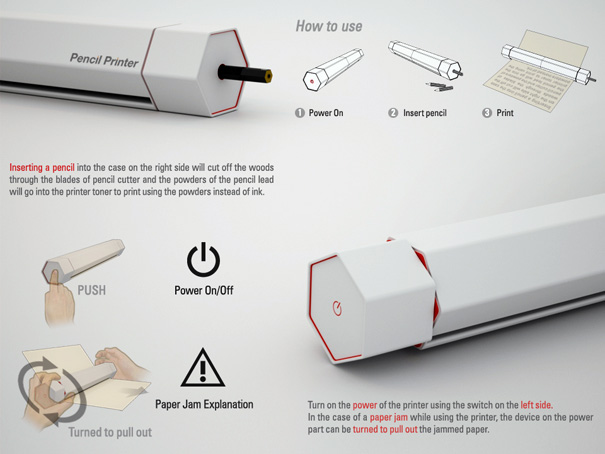

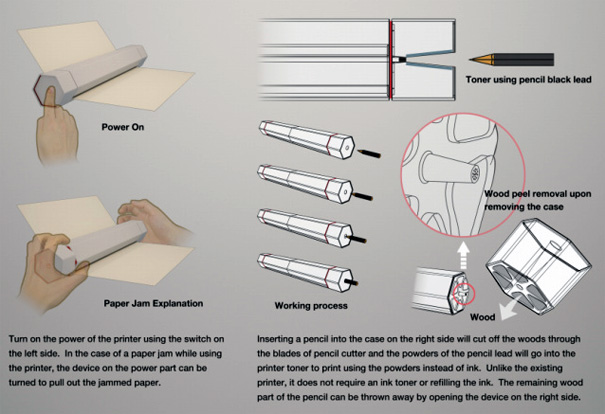

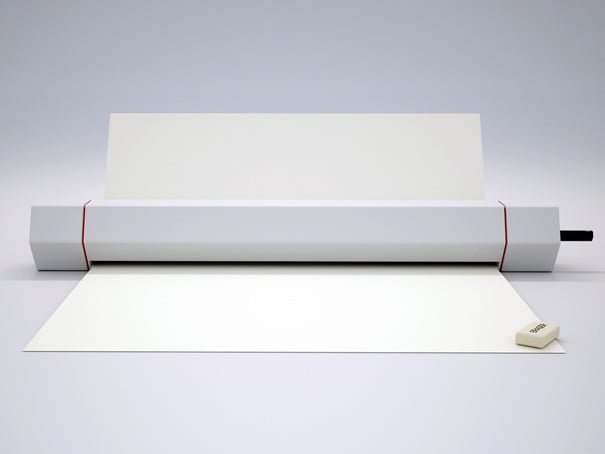

The refined Pencil Printer part II comes with detailed explanations and a better understand of saving the environment from paper trash and permanency of Ink! In here we see how the lead shavings feed the cartridge toner and prints effortlessly on paper. Mistakes are easily erased, and once the crappy memo is done with…you can erase all the gibberish and re-use the paper. A true test of erasing skills!

Designers: Hoyoung Lee, Seunghwa Jeong & Jin-young Yoon

Posted by gjblass at 3:40 PM 0 comments

Labels: 3-d printer, Digital Printing, New Technologies

By Alan Brandon

From: http://www.gizmag.com/

The Ortery Photosimile 5000 desktop photography studio

Image Gallery (6 images)Imagine if you could take professional-looking photos and create 3D product animations as easily as using the office copier. Ortery’s Photosimile 5000 system aims to bring that capability to the office by enabling even non-photographers to create high-quality images just by pressing a few buttons. The Photosimile 5000 is a PC-controlled desktop photography studio that integrates a light box, a DSLR camera, automated camera positioning, and specialized workflow software to simplify and automate business photography.

High-quality images are a powerful part of a company’s web presence and marketing collateral. Ortery's desktop studios are designed to make it easy to create professional-looking product photos for use on web sites, in print, and in email for daily business communications. Crisp, well lit images are essential for ecommerce websites, and the Photosimile 5000 adds the ability to produce 3D, 360-degree product animations as well.

The camera and light box connect to a PC using USB. The Photosimile 5000 software controls the studio, camera location, turntable movement, camera settings, picture taking, and post processing. Simply place an item inside the light box then compose your image using the preview, zoom, and crop commands in the software. With one click, the picture automatically downloads to the PC.

Often the difference between professional photography and amateur work is the lighting. The Photosimile 5000 starts by providing consistent, even lighting for shadow-free images and accurate color. The system uses four daylight bulbs providing 6500K illumination. The Photosimile 5000 also includes a Canon DSLR mounted on a mechanical track. You control the position, tilt, and zoom from the PC. The subject of your photo sits on an Ortery turntable, which the company also offers separately. For 360-degree imaging, the camera position is controlled automatically. The Photosimile can accommodate objects up to roughly 22in. (56cm) on each side. For 3D images the maximum size is somewhat smaller.

The Photosimile 5000 synchronizes the position of the turntable and camera to photograph objects from multiple angles in one or more planes. The combination of the turntable and the mechanical track allow the Photosimile 5000 to shoot up to 72 pictures per 360-degree rotation, at nine unique angles from 0 to 90 degrees. The resulting images can be automatically stitched together to create 360-degree product animations. These 3D views can be saved as GIF or Flash files, or exported to Ortery’s Real3D format. Real3D allows you to compose 3D Silverlight animations with mouse control and zoom capabilities. Ortery says the software can combine images to create 360-degree spherical or hemispherical or animations.

The Photosimile 5000 software controls every aspect of the studio including the camera settings, the camera positioning, turntable movement, picture taking, and image post-processing. The software displays a real-time live preview while you compose your picture with the preview, zoom, and crop controls. The software also provides a complete workflow for annotating, masking, and batch processing files including naming, resizing, watermarking, and saving.

Although the system was unveiled in 2008, Ortery recently announced that the Photosimile 5000 is now shipping. Ortery doesn't list pricing, but at least one dealer on the Internet lists the Photosimile at around US$17000.

For more information and some cool 3D samples, visit Ortery technologies at ortery.com.

Posted by gjblass at 12:36 PM 0 comments

Labels: 3-d printer, 3D, Adobe Flash, dslr, Microsoft Silverlight Player, Office, office furniture

This is an object printed from powdered glass, using the Solheim Lab's new Vitraglyphic process. Credit: University of Washington

A team of engineers and artists working at the University of Washington's Solheim Rapid Manufacturing Laboratory has developed a way to create glass objects using a conventional 3-D printer. The technique allows a new material to be used in such devices.

The team's method, which it named the Vitraglyphic process, is a follow-up to the Solheim Lab's success last spring printing with ceramics.

"It became clear that if we could get a material into powder form at about 20 microns we could print just about anything," said Mark Ganter, a UW professor of mechanical engineering and co-director of the Solheim Lab. (Twenty microns is less than one thousandth of an inch.)

Three-dimensional printers are used as a cheap, fast way to build prototype parts. In a typical powder-based 3-D printing system, a thin layer of powder is spread over a platform and software directs an inkjet printer to deposit droplets of binder solution only where needed. The binder reacts with the powder to bind the particles together and create a 3-D object.

Glass powder doesn't readily absorb liquid, however, so the approach used with ceramic printing had to be radically altered.

"Using our normal process to print objects produced gelatin-like parts when we used glass powders," said mechanical engineering graduate student Grant Marchelli, who led the experimentation. "We had to reformulate our approach for both powder and binder."

By adjusting the ratio of powder to liquid the team found a way to build solid parts out of powdered glass purchased from Spectrum Glass in Woodinville, Wash. Their successful formulation held together and fused when heated to the required temperature.

Glass is a material that can be transparent or opaque, but is distinguished as an inorganic material (one which contains no carbon) that solidifies from a molten state without the molecules forming an ordered crystalline structure. Glass molecules remain in a disordered state, so glass is technically a super-cooled liquid rather than a true solid.

In an instance of new technology rediscovering and building on the past, Ganter points out that 3-D printed glass bears remarkable similarities to pate de verre, a technique for creating glassware. In pate de verre, glass powder is mixed with a binding material such as egg white or enamel, placed in a mold and fired. The technique dates from early Egyptian times. With 3-D printing the technique takes on a modern twist.

Grant Marchelli, a UW mechanical engineering graduate student, removes a new object from the Solheim Lab printer. Marchelli led development of the first method for 3-D printing in glass. Credit: University of Washington

As with its ceramics 3-D printing recipe, the Solheim lab is releasing its method of printing glass for general use."By publishing these recipes without proprietary claims, we hope to encourage further experimentation and innovation within artistic and design communities," said Duane Storti, a UW associate professor of mechanical engineering and co-director of the Solheim Lab.

Artist Meghan Trainor, a graduate student in the UW's Center for Digital Arts and Experimental Media working at the Solheim Lab, was the first to use the new method to produce objects other than test shapes.

"Creating kiln-fired glass objects from digital models gives my ideas an immediate material permanence, which is a key factor in my explorations of digital art forms," Trainor said. "Moving from idea to design to printed part in such a short period of time creates an engaging iterative process where the glass objects form part of a tactile feedback loop."

Ronald Rael, an assistant professor of architecture at the University of California, Berkeley, has been working with the Solheim Lab to set up his own 3-D printer. Rael is working on new kinds of ceramic bricks that can be used for evaporative cooling systems.

"3-D printing in glass has huge potential for changing the thinking about applications of glass in architecture," Rael said. "Before now, there was no good method of rapid prototyping in glass, so testing designs is an expensive, time-consuming process." Rael adds that 3-D printing allows one to insert different forms of glass to change the performance of the material at specific positions as required by the design.

The new method would also create a way to repurpose used glass for new functions, Ganter said. He sees recycled glass as a low-cost material that can help bring 3-D printing within the budget of a broader community of artists and designers.

Source: University of Washington (news : web)Posted by gjblass at 3:42 PM 0 comments

Labels: 3-d printer, Solheim Lab, University of Washington, Vitraglyphic process

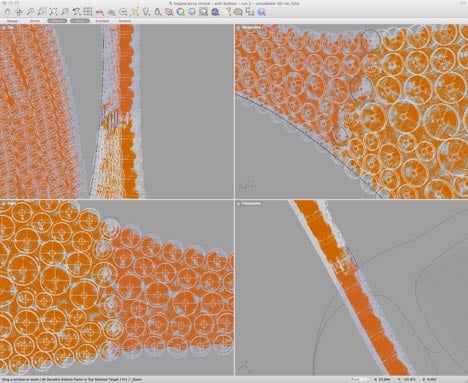

The MakerBot CupCake CNC 3D printer caught my eye from all the way across the room, and MakerBot founder Bre Pettis didn't seem all that surprised that his seemingly cobbled-together DIY Frankenmachine made from wood, acrylic plastic, PCB and messy wires was drawing a crowd. After all, it was artfully melting lumps of ABS plastic into 3D marvels. For $750, it could do the same for you.

The machine gets its name since you really won't be able to make anything larger than a cupcake. But, oh, what you can make. Pettis showed us a replica of the Empire State Building (sans antenna — thanks Matt Buchanan) made from images found on Google, which was rendered with impressive detail. Pettis also showed a more practical use for the 3D printer, when he made a working lens cap for a camera.

If you're squeamish about building it yourself, you can also buy a pre-assembled CupCake for $2,500. There are also plans at MakerBot to develop a 3D scanner, so you can faithfully replicate complex objects.

Get a closer look at the MakerBot CupCake down below, or click Continue to see a high-res image of that model building. It's also worth the trip over to Gizmodo, where you can see it in action.

|  |

|

Just check out that detail (click it to make it big):

Via MakerBot

Posted by gjblass at 9:39 AM 0 comments

Labels: 3-d printer, DIY, Makerbot

Jay Leno has a lot of old cars with a lot of obsolete parts. When he needs to replace these parts, he skips the error-prone machinist and goes to his rapid prototyping 3D printer. Simply scan, print and repeat.

Posted by gjblass at 2:17 PM 0 comments

Labels: 3-d printer, Jay leno, Jay Lenos Garage